Philadelphia Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma is a proven method of improving processes and organizations. Over the years, it has been demonstrated to be both durable and demonstrable in its application. Its structured approach allows organizations to see tangible results and strive for continuous improvement. We are experts in it at Lean Six Sigma Curriculum for Philadelphia High Students of Pennsylvania and make sure that anyone interested in learning how this methodology works can do so by accessing training and basic knowledge with our team. We start with Lean Six Sigma history, which is something that most experts neglect to teach.

First, this method was designed to help companies concentrate on customer satisfaction and reduce waste. It also helps identify and solve problems, so the processes and cycles are improved continuously.

Then, they have greater control over their processes so that mistakes don’t happen again and new problems don’t arise.

It is designed to guarantee that quality and performance are at the highest levels. Since it was originally used in manufacturing, it makes sense that it is most commonly implemented in this sector.

This approach, in addition to the goals mentioned above, reduces lead time and makes use of existing knowledge and experience from all parties.

LSS is an important turning point for many businesses and individuals today who can implement it and help others in the industry that it was intended for.

It is important to understand that LSS was intended to be an “answer” for the Japanese Kaizen method as the latter allowed Japanese companies to improve their processes, reduce waste and increase customer satisfaction by manufacturing the products.

Japan’s productivity and efficiency left American companies behind. Therefore, LSS was created as a way to find a solution so that USA businesses could remain competitive.

What Made Sigma Possible?

Many techniques and methodologies have influenced our current methodology, many of which are actually Japanese:

- Kanban is a method for workflow management. You can improve your productivity and efficiency by visualizing the work and limiting it to a specific time.

- Kaizen will promote self-development, continuous improvement, and customer satisfaction.

- Value stream mapping for optimizing process delivery.

However, the main source for LSS comes from combining Lean and 6 Sigma, the two individual methodologies, which led to a complete methodology that would impact the industry and help American companies.

What is Lean, and What is 6 Sigma?

Toyota developed Lean manufacturing in the late 1940s. This was to reduce non-value-adding activities as it would identify waste and work on its elimination.

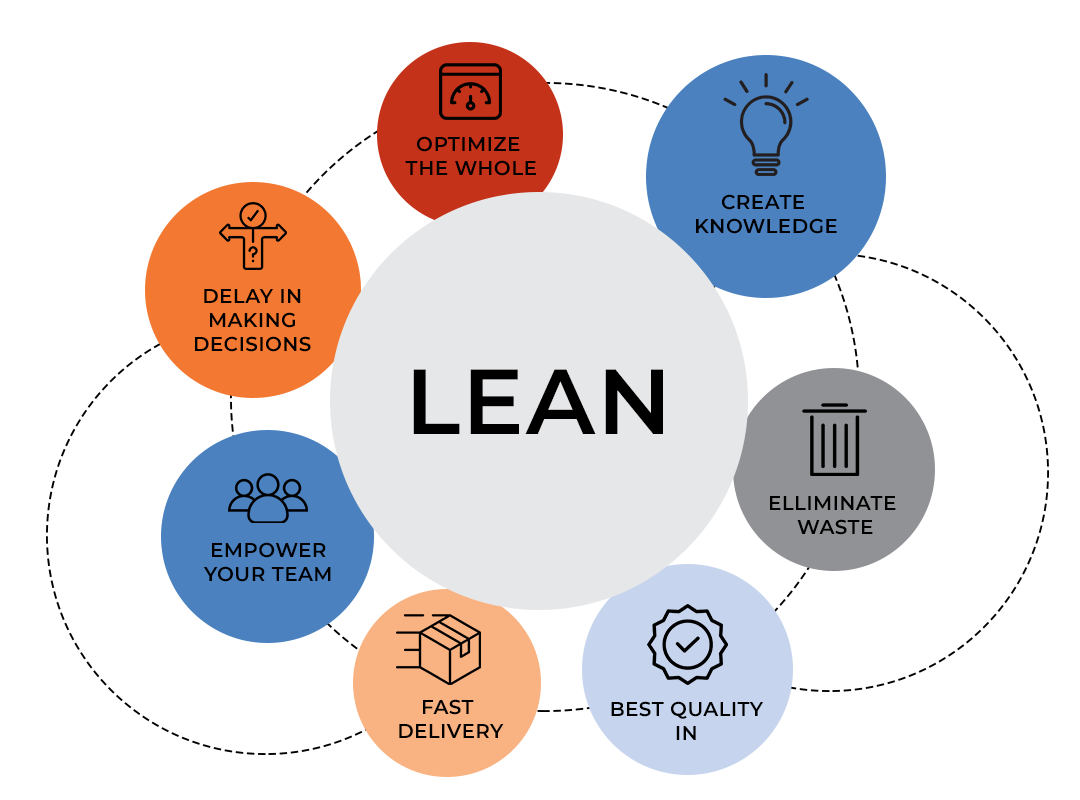

Lean’s core values include:

- Your guide is your customers’ perspective.

- Reduce all work-related waste.

- Keep improving.

This idea suggests that employees should actively participate in organizational change to foster an environment of excellence. Lean encourages continuous learning and improvement.

Toyota Production Systems (TPS), which is the source of Lean’s foundations, was founded by Japanese Taiichi Ohno. Lean was founded upon Henry Ford’s innovations, Business Process Redesign, and other details as well, so there’s more than just the basics of TPS around it.

How does Lean work? This structure will help:

- Lean begins with determining the customer’s added worth.

- All streams and processes should be mapped.

- This will allow you to identify wastes and increase your flow.

- Next, you need to learn how to set up processes and systems so that they can start when a customer requests a product and continue until it is delivered.

- Employees will be able to identify areas where they can improve and work together to find solutions.

Next, Six Sigma was created a few years before LSS. It is much more data-driven than Lean and aims to identify and solve problems.

Motorola developed the method, and General Electric has used it successfully. Six Sigma is a process improvement technique that can be applied to many industries and projects. It offers the following structure: Define, Measure, Analyze. Improve, Control (DMAIC).

It helps to identify the root cause of any problem and implement a solution. DMAIC helps practitioners and employees to maximize their capabilities and deliver the highest value to customers.

Six Sigma provides managers with tools and targets to help them create a structured improvement plan.

When combined, you get a methodology that addresses different approaches to ensure a company is growing and succeeding.

Lean Six Sigma’s Evolution In the USA

This methodology was a great addition to the industry in order to compete with Japanese businesses. It improved processes, eliminated waste, and allowed for growth without compromising customer satisfaction.

Although Lean Six Sigma is still used in the USA’s manufacturing industry, practitioners have discovered ways to adapt it for others. However, goals and needs must be established beforehand.

Healthcare, education, and other industries can all reap the benefits from Lean Six Sigma’s implementation. After training and certification, students or professionals can have a new methodology in their curriculums.

We can help you get trained and learn about LSS at Lean Six Sigma Curriculum Pros of Philadelphia. We will work hard so all your students, workers, or you alone, can be part of history by taking part in the LSS industry.